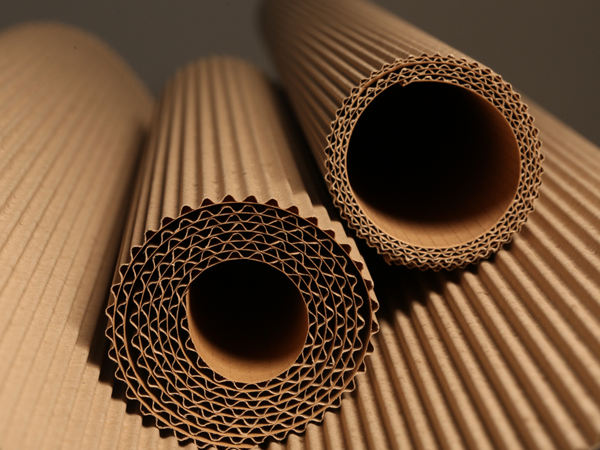

What is Corrugated Roll ?

“A corrugated roll is a packaging material made of corrugated fiberboard. It is a continuous sheet of corrugated cardboard that is rolled onto a spool. Corrugated rolls are commonly used as a protective packaging material for fragile and delicate items during transit or storage.”

History of Corrugated Rolls in Brief Below:

The origins of corrugated paper date back to the early 19th century. In 1856, Englishman Albert Jones patented the first corrugated cardboard, which he used to line tall hats. However, it was not until the 1870s that corrugated paper began to be used for packaging.Today, corrugated paperboard is one of the most widely used packaging materials in the world, with an estimated 200 billion square feet produced annually. Corrugated rolls remain a popular choice for packaging and shipping due to their versatility, cost-effectiveness, and eco-friendliness.

Making of Corrugated Rolls in Brief Below:

The process of making corrugated rolls involves several steps:

Paper making: The first step in making corrugated rolls is to create the paper that will be used. This involves pulping wood chips, mixing them with water and chemicals, and then forming the pulp into sheets.

Corrugating: Once the paper sheets are made, they are fed through a corrugating machine. This machine sandwiches the paper between two corrugated boards, and then passes them through a series of heated rollers to create the characteristic wavy shape of corrugated cardboard.

Cutting and scoring: The corrugated cardboard is then cut and scored to the desired size and shape. This is typically done using large machines that can handle large rolls of corrugated cardboard.

Gluing: Once the corrugated rolls are cut and scored, they are then glued together using an adhesive. The glue is typically applied to the flutes of the corrugated cardboard, and then the layers are pressed together to create a strong bond.

Packing: Finally, the finished corrugated rolls are packed and shipped to customers for use as packaging material.

Corrugated Box Benefits

Corrugated rolls can be easily cut to size, making them a versatile packaging material that can be used for a wide range of applications.

Protection – The corrugated design of the rolls provides excellent protection for fragile or delicate items during shipping and handling. The cushioning effect of the corrugated material helps to absorb shocks and prevent damage to the contents of the package.

Lightweight – Corrugated rolls are lightweight, which makes them easy to handle and transport. They also help to keep shipping costs down by reducing the weight of the package.

Cost-effective – Corrugated rolls are relatively inexpensive to produce and are widely available, making them a cost-effective option for packaging and shipping.

Environmentally friendly – Corrugated rolls are made from recycled materials and are themselves recyclable. They are also biodegradable and can be easily disposed of in an environmentally friendly manner.

Specifications:

| Flute size : | Corrugated rolls are available in several different flute sizes, which affect their strength and cushioning ability. The most common flute sizes are A, B, C, E, and F, with A being the smallest and F being the largest. |

| Board thickness : | Corrugated rolls are available in different thicknesses, typically measured in points or millimeters. The thickness of the board can affect its strength and rigidity. |

| Board material : | Corrugated rolls are typically made from recycled paper or other fibers, which can affect their strength, durability, and environmental impact. |

| Roll width and length : | Corrugated rolls can be customized to fit specific applications, with widths typically ranging from 12 inches to 72 inches and lengths ranging from 50 to 200 feet. |

| Surface finish : | Corrugated rolls can come in different surface finishes, such as kraft, white, or coated, depending on the desired appearance and printing requirements. |